What do you know about table sugar? And the common misconception that raw and unrefined sugars are healthier than refined sugar.

Sugar is made by some plants to store energy that they don't need straight away, rather like animals make fat. People like sugar for its sweetness and its energy so some of these plants are grown commercially to extract the sugar.

What we call table sugar, chemist know as 'sucrose', one of

the family of sugars otherwise known as saccharides in the grouping called

carbohydrates. Carbohydrates, as the name implies, contain carbon and hydrogen

plus oxygen in the same ratio as in water. The saccharides is a large family

with the general formula CnH2nOn. The simplest of the sugars is glucose, C6H12O6,

although its physical chemistry is not that simple because it occurs in two

distinct forms which affect some of its properties. Sucrose, C12H22O11,

is a disaccharide, a condensation molecule made up of two glucose molecules.

The process whereby plants make sugars is photosynthesis. The

plant takes in carbon (IV) oxide from the air through pores in its leaves and

absorbs water through its roots. These are combined to make sugar using energy

from the sun and with the help of a substance called chlorophyll. Chlorophyll

is green which allows it to absorb the sun's energy more readily and which, of

course, gives the plants' leaves their green colour. The reaction of

photosynthesis can be written as the following chemical equation when sucrose

is being made:

|

12 CO2 + 11 H2 O |

→ |

C12 H22 O11 + 12 O2 |

|

carbon (IV) oxide +

water |

→ |

sucrose + oxygen |

Sucrose is found in the stems of sugar cane and roots of

sugar beetle. It also occurs alongside glucose and fructose in other plants

particularly in some roots like carrots and other fruits.

Sugar cane is composed of approximately 70% water, 15%

soluble substances and 15% insoluble substances. In the 15% soluble substances

only 12% is sucrose and the rest is fructose and glucose. More than 60% of the world’s sugar production

is from sugar cane; the balance is from sugar beet.

For processing sugar beet (water 75%; sugar 17%), only the

washing, preparation, and extraction processes are different. After washing,

the beet is sliced, and the slices are drawn into a slowly rotating diffuser

where a counter current flow of water is used to remove sugar from the beet

slices. Sugar refining involves removal of impurities and decolorization. The

steps generally followed include affinition (mingling and centrifugation),

melting, clarification, decolorization, evaporation, crystallization, and

finishing. Decolorization methods use granular activated carbon, powdered

activated carbon, ion exchange resins, and other materials.

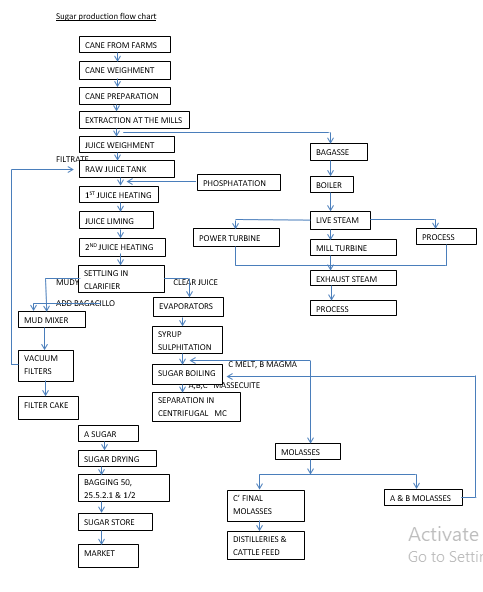

The flow chart below illustrates sugar production process from sugarcane

The cane received in the factory yard is fed to the carrier

by mechanical unloader from tractors while the cane carriers are manually emptied.

The cane is passed through preparatory devise like knives, for fine cutting

before being subjected to crushing in a milling tandem comprising 4 roller

mills. The mills are of modern design, being equipped by turbine drive, special

feeding devices efficient compound imbibition system.

The raw juice from milling station is weighed while being

treated with phosphoric acid; it’s then heated in primary heater and treated

with lime solution for removal of impurities in suspension. The treated juice

on boiling in the secondary heaters is fed to the clarifier from which the

clear juice is decanted while the settled impurities known as mud are sent to

continuous vacuum filter for filter for removal of unwanted stuff.

The clear juice with about 73- 75% water is concentrated in

a multiple effect evaporator under vacuum to yield syrup with about 37- 43%

water content. They used to treat syrup with Sulphur (IV) oxide before being

sent to pan station for crystallization of sugar, for whitening but Sulphur

(IV) oxide was later banned for health reasons.

It is at the vacuum pan boiling stage that the sugar

crystals appear. The crystal containing mass from the pan is dropped in the

crystallizers and subsequently centrifuged in centrifugal machines for

isolating sugar crystals from mother liquor, which again is sent to pan for

boiling and recrystallization. Three stages of recrystallization are adopted to

ensure maximum recovery of sugar in crystal form. The final mother liquor

referred to as final molasses is sent out of factory as waste being unsuitable

for recovery of sugar under commercial conditions from economic point of view.

Under these conditions sugarcane processing yields –

(a) 27- 30%

bagasse containing around 46% fiber

(b) 3.55%

filter cake containing 30% dry matter

(c) About 4%

final molasses containing 80% dry matter besides about 10.5 – 12% crystal sugar

which is principal product of manufacture.

In raw sugar manufacture, the raw juice after addition of required dose of phosphates is heated to 70c and treated with lime to a pH of 7.2 – 7.4. Further heating to 100c followed by separation of clear juice by decantation in clarifier and subsequent processing steps are the same as followed in white sugar manufacture with the exception of elimination of melting of low grade sugar and washing of final product of manufacture. The sugar produced is of 98.5 polarization and the crystals are surrounded by thin layer of molasses presenting brownish appearance.

Based on the types of sugar produced the cane sugar

factories can be classified into four categories as under —

(i) Raw Sugar—In many sugar producing areas raw sugar of 98-99 purity is produced from cane, which is sent to refineries or exported. This sugar can later be converted into refined sugar of very high purity.

(ii) Refined Sugar—White and sparkling in appearance the refined sugar is of 99.9 purity and is used directly for human consumption, besides a small proportion for pharmaceutical and chemical industries.

(iii) Raw Sugar Factories-cum refineries— In these factories producing raw sugar from sugar cane, small refining units are installed for processing the raw sugar and manufacture of refined sugar. The refinery can operate throughout the year even though the raw sugar production is confined to the crushing campaign restricted to dry periods of the year.

(iv)

Plantation white sugar factories—In some of the

developing countries white sugar is manufactured from cane for direct

consumption employing more complicated techniques in clarification of juice and

also in crystallization of sugar. The sugar produced is of 99 - 99.8% purity

and contains slightly higher amount of impurities than the refined sugar. These

plants can also produce raw sugar either for export or supply to refineries.

Raw and refined sugar

Both raw and refined sugar start out the same way, as sugar

cane. Raw sugar (also referred to as unprocessed sugar) has large crystals,

have a slight golden brown colour and retain a thin layer of molasses.

Refined sugar continues along the manufacturing process. In

sugar processing, the term “refined” means the same thing as purified. White

sugar is combined with naturally occurring minerals to strip away

impurities. The sugar is washed and

filtered through carbon, decolorized and recrystallized. This purified sugar is further processed into

a fine crystal form, dried and passed through multiple screens to remove

mineral and impurities before it is packaged.

Over the years, refined sugar has gotten a bad rap. It is

not the overly processed or manipulated product that some make it out to be. The

refining process just makes sugar “more pure.”

When baking, it is important to stick to the type of sugar

the recipe calls for. Raw Sugar and refined sugar are not interchangeable. Raw

sugar does not dissolve as easily as refined sugar. It holds its shape when

heated, making it good for crunchy toppings on sugar cookies or muffins, but

not so great in cakes or puddings where smoothness and moisture is desired.

Plus raw sugar retains a small hint of molasses flavor, which can change the

taste profile of your recipe.

What is the healthiest

Sugar?

Cane sugars are an excellent source of calories—mostly from sucrose. However, they are not a significant source of any other nutrient. One exception is cane molasses, which is a good source of minerals, but we don't eat enough of it to get the health benefits.

A common misconception is that raw and unrefined sugars are healthier than table sugar. Unrefined sweeteners do have slightly more nutrients, such as vitamins, minerals, and antioxidants when compared to refined sugars.

However, the amount per serving is minuscule. We would have to eat a truly unhealthful amount of unrefined sweeteners (100 g or even a cup) to get a daily micronutrient requirement or the positive health effects from them. The calories and sugar content in unrefined sugar outweigh the advantages of antioxidants, vitamins, and minerals.

The Real Reasons to

Choose Unrefined and Raw Sugars

We now know unrefined and raw sugars are not better for our health than refined sugars. They are not much different in terms of nutritional value. But if you’re thinking, is unrefined sugar better for baking? Is raw sugar better than white sugar for my coffee? The answer is yes.

The real reasons to choose unrefined and raw sugars include:

• They offer a unique taste and aroma

Unrefined and raw sugars have the same sweetness as table

sugar, but they offer a more complex flavor. Raw sugars, such as turbinado,

demerara, and organic cane sugar, have a delicate molasses taste and aroma.

They are perfect to add a hint of flavor to coffee, tea, cappuccino, latte, and

cocktails. Sprinkle over cereals and fruits. Blend with cinnamon and sprinkle

over waffles, French toast, or pancakes.

On the other hand, unrefined sugars provide a more robust

lingering molasses flavor. They pair well with ginger, coffee, chocolate,

vanilla, butterscotch, and cinnamon.

• They give a boost to beverages, cooking, and baking goods

Unrefined sugars add depth to baked goods—brownie, banana

bread, chocolate chip cookies—rib rubs, barbecue sauces, beef stews, and hot

chili. Try it over your hot cereals, French toast, ice cream, hot chocolate,

granola bars, and cinnamon rolls. Cookies will be less crisp but chewier,

whenever we remove a dryer sweetener and substitute it with another with higher

moisture and stickier such as muscovado sugars.

Raw sugars have an attractive sparkly crystal, and those

labeled as demerara have coarse crystals.

Because they hold their shape when heated, use them as a finishing sugar

to add a crunchy topping to cookies and muffins.

• They are a one-to-one substitute for refined sugars

Unrefined sugars are perfect 1:1 substitutes in any recipe calling for regular refined brown sugars. For the most part, you can directly swap table sugar with unrefined and raw sugars in cookies and some cakes [but not for fine-textured and fancy cakes, puddings, or desserts where smoothness is desired].

The Bottom Line

All cane sugars are refined to some extent, even the

so-called "raw" and "unrefined" — which are only slightly

less refined and, in terms of nutritional value, not much different from white

sugars. If a less processed sweetener is what you are looking for, then try raw

and unrefined sugars.

One cane sugar is not necessarily better than another. Each

one works well for some applications and not for others. The benefits of

sweeteners such as turbinado, demerara, and muscovado come from their unique

taste, aroma, and that no-guilt inducing sensation they offer us.

Comments

Post a Comment